50+

Years Experience Working

WELCOME TO OUR COMPANY

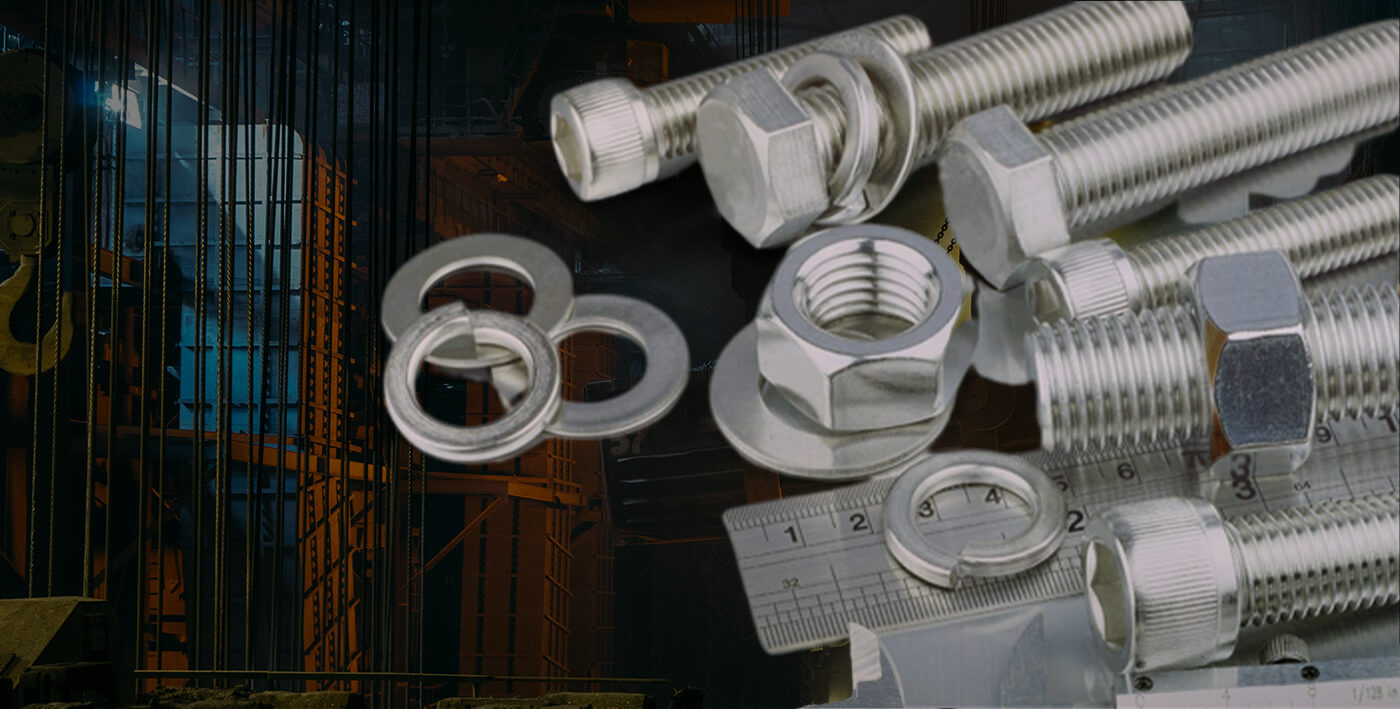

About Capital Bolts And Hardwares

Capital Bolts & Hardware's is a ISO and CE & IATF 1649:2016 certified Fasteners Manufacturer well-known name among the topmost suppliers and manufacturers of premium quality fasteners. It was founded by Mr. Ramprakash Nagpal in the year 1959, to meet the growing demand for quality products for fixings' applications in the construction works, mechanical equipment, and household appliances. Over the past six decades, Capital Bolts & Hardwares has grown under the energetic leadership of 3 generations and evolved as a large scale company of premium fastening products. Quality checks and activity control at each stage are followed as a custom to ensure to deliver value to the customer. Capital bolts and hardware's is ISO certified and CE certified and IATF Certified Fasteners Manufacturer company.

- The Leading supplier and manufacturer in the world of Fasteners.

- Quality, Product Standard and Service commitment.

- Known for a wide product range availability.

OUR STRENGTHS

Our company is one of the largest Fasteners Manufacturers & Fasteners Suppliers of Fasteners Exporters in India.Quality

CBH fasteners are fully organized to ensure complete compliance with industry and customer specifications. Our on-site laboratory is fully equipped to catch even a small flaw in quality. We have equipment ranging from UTM, hardness testers, alco meters, ring, and plug gauges, impact testing, code friction to Spectrometer, and many more.We have a dedicated team of quality personnel who ensure strict quality checks at every step whether we manufacture the products in-house or at our approved vendors. Our quality and procurement team ensures that quality products are procured timely according to the dispatch schedule.

Our Quality Tests include:

Chemical Analysis –Spectrometer: Confirm that the right raw material is used and the finished product as per customer material requirement/specification.Machinal Analysis - Universal testing machine (UTM): Used to test the tensile, proof load, and wedge load of the fasteners like nut, bolt, washer, etc. for different grades and material.

Tension Testing – Proof and Tensile: Verifies that the proper strength levels are present with fasteners.

Hardness Testing (Rockwell hardness machine): Penetration of a diamond indenter into the product like Bolts, nuts, washers, etc to determine the hardness of the fasteners.

Impact tester: Used to test the shear strength of the bolts, nuts, washers, and so on.

Alco Meter: Used to test the coating of the fasteners. A coating like Zinc, trivalent Zinc, hot-dip galvanized, etc

Dimensional Testing –Vernier, Micrometre & Hight Gauge - Used to check the Dimension should be as per customer requirement/drawing or international standards like ISO, Din, ASTM, etc.

Thread Gaging – Internal and External: Ring Gauge, Plug Gauge, and Pitch Gauge is used to test the gauge of the product, should be as per standards or customer requirement/drawing for both inch and metric.

Salt Spray Testing: Used to check corrosion resistance of materials and surface coatings in a controlled environment. Testing is performed as per international standards or required by the customer.

Our all equipment’s are time to time calibrated with the proper record. We also believe in keeping up with the new technology implementation in our lab.

CBH produces more than 200000 SKUs which are the maximum for a single company anywhere in the world. We believe in regular improvement and evolving our company to reach goals of optimum efficiency. SAP implementation in the company is a recent example and is another feather in the hat. We have recently shifted our company to SAP and we have designed it to counter all the bottlenecks in supply chain management.

CBH has an internal and external Audit team that is regularly working on employee improvement, company processes refinement, and compliances implementation according to ISO standards.

We have also applied 5S in our warehouse, which in itself is a world-class facility.

One-Stop-Shop

CBH has the widest range of products under one roof. We can boast of being the largest fastener company in India in terms of the widest range of SKUs under one roof. And to top it all, all these products are available at the best prices with the best quality.We have a network of more than 200 approved vendors in Pan India who meet our requirements for such a wide range of SKUs. Our procurement and quality team is regularly monitoring the procurement process by regularly visiting our vendors to ensure quality and timely procurement.

Any product marked CBH speaks for itself in terms of quality and how much effort our team (more than 100 people) has in production and procurement.

Reach

CBH has the widest reach of its products across all industry verticals and the Globe.We have the widest distribution network pan India and a long list of OEM customers across the country. Our global reach covers all the five continents such as America, Africa, Asia, Australia, and Europe.

We have a presence in over 50 countries across the Globe.

Social Responsibility

CBH realizes that it has a responsibility towards its society.We ensure that we donate a fixed percentage of our profits to weaker sections of society. We have tie-ups with many NGOs who are working in the fields of Health, Education, development of the girl child, etc. Team CBH engages in monthly activities to achieve our target of Corporate Social Responsibility.

Employee Satisfaction

CBH strives to reach optimum employee satisfaction and skill development by providing regular training and a world-class work environment. Our employee satisfaction levels are high and we have had some people working for us for even more than 30 years.We ensure optimum safety for our employees at work according to ISO norms.

We ensure that our employees and their families are taken good care of by the company.

Environmental Responsibility

We at CBH ensure that we achieve our growth targets without harming the environment and here are a few steps taken by the companyROHS Compliance: Our plating plants are ROHS compliant and we ensure no harmful chemicals are used in our manufacturing processes

Solar Energy: More than 50% of our energy consumption comes from our solar plant installed at our premises.

Water recycling is a part of our endeavor to ensure the safety of our environment.

We use recycled paper in our packing process and we ensure minimum use of plastics in our packaging.

Growth Targets

We have a target to cross a turnover mark of 5 million USD this year and grow to 10 million next year. We are eyeing doubling our turnover year on a year basis So, let's join hands and grow together and associate for a long-term relationship.INDUSTRIES WE SERVE

Quality With Dedication

We are successfully exporting them worldwide in countries like Russia, South America, Central America, Europe and 40 more countries |